|

|

Casteel's strength cannot be eclipsed. Whether its strength is needed for retaining soil or for drivability, steel remains the strongest sheet piling material available. Casteel sections are quite useful for an array of applications including seawalls, cutoff walls, trenches and jetties.

|

|

Why Steel? |

|

Steel's unsurpassed structural capacity and homogenous nature allow steel sheet piling to resist deflection, crippling, and impact related problems. Its rigidity, drivability, and strength translate into labor-saving design options that are simply not possible using synthetic sheet piling. |

|

A material's modulus of elasticity is a measurement of its stiffness or rigidity. FRP, vinyl, and steel all exhibit significantly different modulus values. This modulus contributes to a sheet pile's efficacy in the field. It increases its drivability, improves its resistance to deflection, and allows it to attain higher moment capacities; in other words, the higher a sheet pile's modulus of elasticity, the better its overall performance.

Cantilever Option

Because of steel's superior stiffness, certain design options are only suitable for steel or materials with similar stiffness. One such option is a cantilever, or free standing design. Cantilever walls require less construction time and less excavation. This converts into lower installation costs, when compared to a tied-back wall.

|

|

| Modulus of Elasticity |

|

| Steel |

30,000,000 psi |

|

| FRP |

2,800,000 psi |

|

| Vinyl |

380,000 psi |

|

Installing anchored walls requires excavation 10' - 20' behind the wall; homeowners love the cantilever option because it creates less disturbance to their property.

|

|

|

|

|

|

|

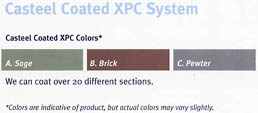

Casteel XPC (Extreme Performance Coating) provides the highest level of protection against harsh saltwater environments, varying soil conditions, exposure to the atmosphere and industrial pollution. |

|

The XPC system was developed by a collective effort of industry experts representing the fields of chemistry, metallurgy, application technology and steel manufacturing.

Casteel XPC is specifically engineered with a high quality epoxy anti-corrosive that offers tremendous abrasion resistance. Applied at one of the most technically advanced and experienced marine application coating facilities in the United States, Casteel sheet piling sections are pre-treated using a Near White Blast Cleaning procedure. A 12-14 mil coating is then applied by a multiple pass airless spray technique. The result is excellent long-term, corrosion defense in even the most extreme conditions.

Formulated with SigmaPrime®, Casteel XPC assures long-lasting protection substantiated by SigmaPrime's® extensive use in the World Wide ship building industry. Casteel XPC is monitored to achieve the highest quality by obtaining maximum performance from the epoxy polymer and its chemical bond with the surface of the steel. This forms an aesthetically appealing cladding that is resistant to impact and abrasion.

XPC's corrosion-inhibiting shield allows Sheeting Solutions to offer economical solutions by significantly increasing the service life of its steel piling. When designed around the serviceability of this heavy-duty epoxy, the life span will be significantly extended even for the lightest steel sheet piling sections.

|

|

|

|

| Test Data |

| Catholic Disbondment Testing |

No blistering, rusting or delaminating after six months |

| Salt Spray Testing |

After 2,100 hours, 2 mm creep at scribe |

| Prohesion Testing |

After 1,600 hours, 1 mm creep at scribe and med. #2 blisters at scribe |

| Salt Water Immersion |

No blisters, rusting or delaminating after 6 months immersion |

| Gasoline Immersion |

No blisters, rusting or delaminating after 11 months of immersion |

| Crack Resistance Testing per SM 323-321 |

At 55 mils dft, no cracking after 50 cycles |

| Flexibility (ASTM D522) |

37.1% elongation (1/16" steel with 5-6 mils dft) |

|

|

|

|

|

|