|

|

|

|

|

|

|

|

|

|

|

|

|

Nexgen sheets are moderate-to-heavy duty fiber reinforced polymeric (FRP) sheet piling that are ideal for seawall applications where corrosion resistance is of high concern. Nexgen products have higher strength and stiffness than comparable vinyl sections, but remain lightweight, easy to install and handle.

|

|

|

Nexgen The Next Generation of Sheet Piling |

|

|

|

For more than 25 years, FRP products have established themselves as viable alternatives to concrete and steel. By resisting chemical attack and maintaining its high strength, Nexgen embraces these advantages with its sheet piling.

All Nexgen composite products are pultruded to insure uniform quality and predictable performance. The products are specifically designed to give the greatest longevity at the least possible cost. With this in mind, Nexgen is the next generation in sheet piling. |

|

Composites have long been recognized for their light weight and incredible strength.

Nexgen offers a very high strength-to-weight ratio with panels weighing only 3-5 pounds per square foot.

The low weight translates into a reduction in handling, labor, and transportation costs by using less equipment and manpower.

|

|

|

|

Resign System |

|

|

The resin system is a high performance polyurethane composition. This combination provides the Nexgen sheet piling with excellent elongation/impact strength, extreme temperature resistance, excellent chemical resistance, saltwater tolerance, and natural resistance to UV degradation. For additional UV resistance and strength, the system is modified with carbon pigments, UV stabilizers, and a surface veil for a resin-rich surface.

|

|

Fiber Reinforcement |

|

|

Nexgen is reinforced with biaxial stitched e-glass fabrics, continuous strand glass mat, and aligned unidirectional roving's, with carbon additives. The specially engineered combination of these materials provides the structural strength necessary to withstand the high stresses required by the sheet piling application. All fibers are sized for optimum compatibility with polyurethane and polyester based resin systems. |

|

Material Properties |

|

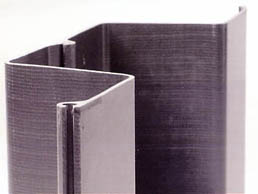

The Nexgen includes a strong interlocking ball and socket joint that maintains alignment between sheets throughout installation.

The typical properties of the sheet pile listed below as tested by an independent third party testing laboratory.

Our testing laboratories are certified ISO 9001 as well as AS 7101 of NADCAP (National Aerospace & Defense Contractor Accreditation Program) and ISO 17025 accredited by A2LA (American Association for Laboratory Accreditation). This insures that our sheet pile has the highest level of reliability and performance. |

|

|

|

| |

|

|

| Peak Tensile Stress (MD) |

100.18 ksi |

ASTM D-3039/D-638 |

| Peak Tensile Stress (XMD) |

15.41 ksi |

ASTM D-3039/D-638 |

| Peak Flexural Stress (MD) |

119 ksi |

ASTM D-790 |

| Peak Flexural Stress (XMD) |

41.22 ksi |

ASTM D-790 |

| Modulus of Elasticity (MD) |

6,113,000 psi |

ASTM D-3039/D-638 |

| Modulus of Elasticity (XMD) |

2,124,000 psi |

ASTM D-3039/D-638 |

| Allowable Shear Strength |

5,600 lbs/ft |

ASTM D2344-84 |

24 hour Water Absorption

|

<--- 0.15%

|

ASTM D-570 |

| (MD) Maching Direction |

(XMD) Cross Machine Direction |

|

|

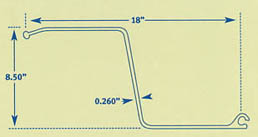

Selection Properties |

| Moment of Inertia |

62.8 in4/lb |

|

| Section Modulus |

14.8 in3/ft |

| Ultimate Moment |

131,250 ft-lb/ft (Strength Rating) |

| Moment with 3.5 SF |

37,500 ft-lb/ft |

| Width |

18.0 in |

| Depth |

8.5 in |

| Weight |

6.5 lbs/lin/ft |

| Mechanical Interlock |

3,300 lbs/ft (Strong FRP interlock made) |

| Color- light & dark gray |

Available in any color at no additional cost |

| Web Thickness |

0.26 inches |

| Flange Thickness |

0.26 inches |

| UV Protection |

Yes-100% UV stabilization |

|

|

|

|

| |

|

|

| Peak Tensile Stress (MD) |

60 ksi |

ASTM D-3039/D-638 |

| Peak Tensile Stress (XMD) |

10.25 ksi |

ASTM D-3039/D-638 |

| Peak Flexural Stress (MD) |

78 ksi |

ASTM D-790 |

| Peak Flexural Stress (XMD) |

32.5 ksi |

ASTM D-790 |

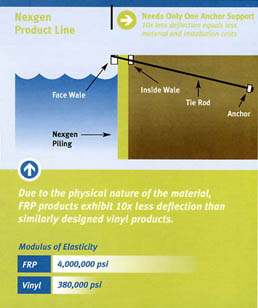

| Modulus of Elasticity (MD) |

4,000,000 psi |

ASTM D-3039/D-638 |

| Modulus of Elasticity (XMD) |

1,700,000 psi |

ASTM D-3039/D-638 |

| Allowable Shear Strength |

4,200 lbs/ft |

ASTM D2344-84 |

24 hour Water Absorption

|

<--- 0.15%

|

ASTM D-570 |

| (MD) Maching Direction |

(XMD) Cross Machine Direction |

|

|

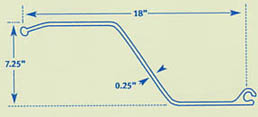

Selection Properties |

| Moment of Inertia |

37.1 in4/lb |

|

| Section Modulus |

10.25 in3/ft |

| Ultimate Moment |

86,310 ft-lb/ft (Strength Rating) |

| Moment with 3.5 SF |

24,660 ft-lb/ft |

| Width |

18.0 in |

| Depth |

7.25 in |

| Weight |

4.7 lbs/lin/ft |

| Mechanical Interlock |

3,000 lbs/ft |

| Color- light & dark gray |

Available in any color at no additional cost |

| Web Thickness |

0.25 inches |

| Flange Thickness |

0.25 inches |

| UV Protection |

Yes-100% UV stabilization |

|

|

|

| |

|

|